For a limited time! FREE SHIPPING ON ORDERS OVER $300 (Only applicable for North America and Europe)

The French are known around the world as masters of candle making, or chandling as it used to be called. The quality of wax, delicacy of fragrance and beauty of design can be attributed to other French artisan industries. The culinary arts, for example, have taught candle makers the importance of textures, timing, and temperatures. The perfume industry, known to be global experts in luxurious scents, based in Provence and Grasse, provides some of the finest ingredients in the world.

Yet before candle makers were mixing raw perfume with wax, candles in France were the only source of illumination for centuries, dating back at least 5,000 years. During the Middle Ages, beeswax became the primary material for wax, which was a huge improvement from animal-based fats, as the beeswax candles burned purely, not sputtering or producing smoke. They were used primarily in religious ceremonies and in the royal houses until beeswax became more commonplace and affordable.

The Royal Opera House at the Palace of Versailles was wisely constructed near the water reservoirs for the fountains, for fear that the theatre, entirely built of wood, could catch fire from the thousands of naked candles used as the only source of light.

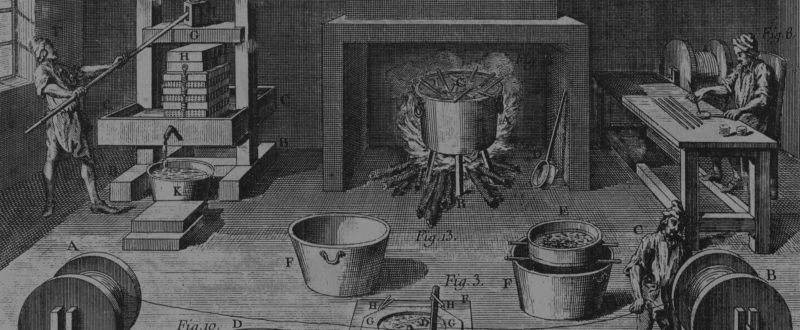

So, how do the modern masters make their candles in France ? It’s a tale of history, science and craftsmanship. We turned to Cire Trudon, established in 1638, and widely regarded as the worlds oldest candle manufacturer, to understand how this all weaves together. The first step is the perfuming. Using olfactory experts here in France, Trudon’s original fragrances are the result of careful testing and development. The raw materials are chosen for their purity and quality, and the wax and flower based materials are mixed in the laboratory, producing a scented wax with superior melting qualities.

Enregistrer